Brewing; beer production process

- Brewing is the process of production of malt beverages. Beers, ale and lagers are the main malt beverages produced by a method called brewing. Brewing is a complex fermentation process. It differs from other industrial fermentation because flavor, aroma, clarity, color, foam production, foam stability and percentage of alcohol are the factors associated with finished product.

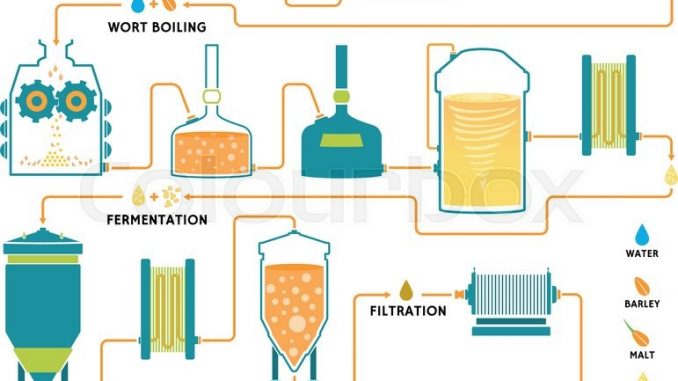

Steps involved in beer production are:

1. Malting:

- Beer is produced from barley grains.

- Barley grains are first cleaned and then soaked in water for about 2 days. Then excess water is drained away and the barley are incubated for 4-5 days to allow germination

- The germination steps allow the formation of highly active α-amylase, β-amylase and proteases enzymes as well as various flavor and color components

-

Malt adjuncts:

- Barley contains considerable amount of protein. So, if only barley are used for beer production, the final beer will be dark and unstable. Therefore, protein present in malt should be diluted by adding additional starch or sugary materials.

- Such sugary or starchy materials are called malt adjuncts and includes dextrose sugar syrup.

-

2. Kilning:

- The germinated seed are then killed by slow heating at 80° This process is called kilning.

- The kilning temperature must not harm amylase enzyme. Furthermore, if kilning temperature is higher, darker will be the beer produced.

3. Mailing:

- The dried barley grains are then crushed between rollers to produced coarse powder called grist

4. Mashing:

- Grist is mixed with warm water and the resulting materials is maintained at 65°C for about 1 hour.

- In doing so, starch is hydrolyzed by amylase enzyme to produce single sugar, maltose, dextrose etc. similarly, protein is hydrolyzed by proteolytic enzymes into small fragments and amino acids.

- The degree of enzymatic hydrolysis is strongly depends on pH and temperature. β-amylase has optimum activity at temperature 57-65°C whereas α-amylase has optimum activity at temperature 70-75°

- The liquid obtained by mashing is called wort. The husks and other grains residue as well as precipitated proteins are removed filtration.

5. Boiling of wort:

- The filtrate is then bolied with stirring for 2-3 hours and hop flowers are added at various interval during boiling.

- Reasons for boiling of wort:

- For extraction of hop flavor from hop flower

- Boiling coagulate remaining protein and partially hydrolyze protein and help in removal of protein

- Boiling inactivates enzymes that were active during mashing, otherwise causes caramelization of sugar

- Boiling also sterilize and concentrate the wort

6. Hops:

- Hops are dried female flower of hop plant Humulus lupulus. Approximately one quarter pound of hop flower is added per barrel of beer and up to 2 pound per barrel of ale.

- Advantages of hop addition in beer are;

- Provide beer with its pungent and aromatic character

- Provide tannin which helps in coagulation of remaining protein

- Contains α-resin and β-resin which gives bitter flavor as well as preservative action against gram Positive bacteria

- Contains pectin which is responsible for foam characteristic of beer

7. Fermentation:

- Beer production utilize strain of Saccharomyces carlsbergens and S. varum which are bottom yeast and S. cerevisiae which is a top yeast.

- Yeast cells for inoculation are usually recover from previous fermentation tank by treatment with phosphoric acid, tartaric acid or ammonium persulphate to reduce the pH and removed considerable bacterial contamination.

- Fermentation is usually carried out at 3-4 °C but it may range from 3- 14° Fermentation usually completes in 14 days.

- During fermentation yeast converts sugar mainly into ethanol and CO2 plus some amount of glycerol and acetic acid.

- For fermentation open tank fermenter can be used however closed fermenter tank is preferred, so that CO2 liberated during fermentation can be collected for later carbonation step.

- CO2 evolution is maximum by fifth day of fermentation, there is no evolution of CO2 by 7-9 days because yeast cells become inactive and flocculate.

- Most beer contains 3.5-5% alcohol.

8. Finishing, Ageing, Maturation and Carbonation:

- The young and green beer is stored in vat at 0°C for several weeks to several months. During this period, precipitation of protein, yeast, resin and other undesirable substances take place and beer become clear.

- Ester and other compounds are also produced during ageing which gives taste and aroma.

- After ageing, the beer is carbonated by carbondioxide of 0.45-0.52%.

- The beer is then cooled, clarified, filtered and packed in bottles, barrels and cans.